Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

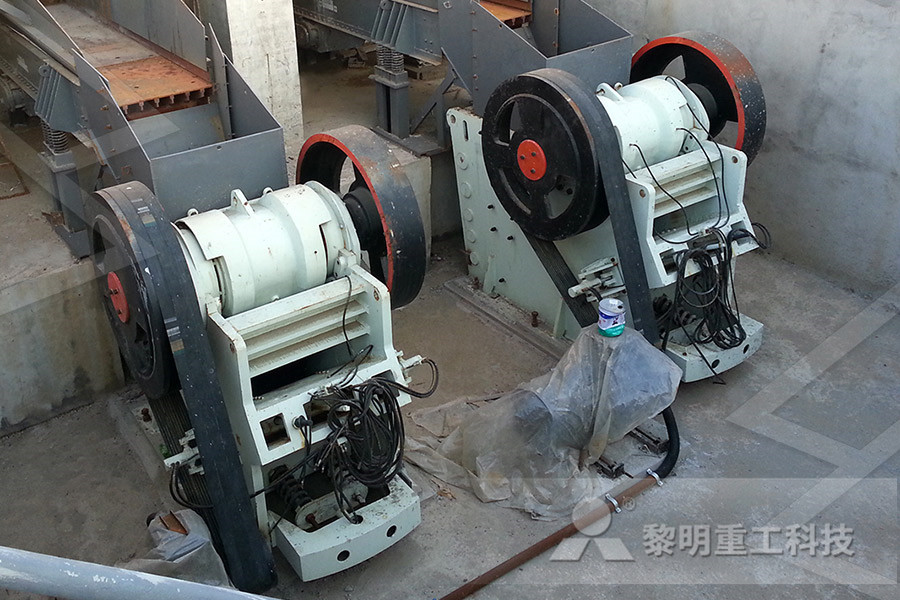

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

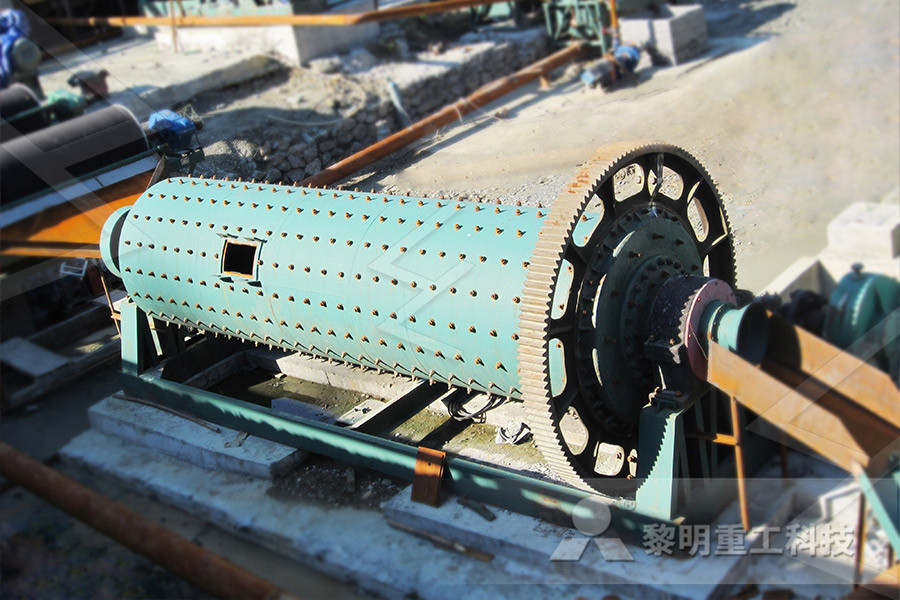

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Can Old Concrete be Crushed for Recycling? FTM

Nov 29, 2019 Jaw Crushers Most recyclers use a jaw crusher for primary crushing because it can handle large pieces of concrete and residual reinforcement An excavator loads the concrete into the jaw crusher then it Mar 01, 2021 Jaw, impact, and cone crushers are the most commonly used types of concrete crushers Jaw crushers act like a nutcracker and “chew” the concrete into smaller pieces until they’re small enough to fit through the machine’s teeth Impact crushers work by either smashing pieces of concrete against hard surfaces or hitting it with a hammer How to Crush Concrete for Recycling RamcoAug 01, 2019 Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 Mpa2 Types of Concrete Crushers

Concrete Foundation Design Jaw Crusher

Nov 29 2019 Jaw Crushers Most recyclers use a jaw crusher for primary crushing because it can handle large pieces of concrete and residual reinforcement An excavator loads the concrete into the jaw crusher then it chew the larger chunks of concrete into smaller pieces It reduces concrete to 6080 mm which can be usually used as fillMcLanahan Universal Jaw Crushers can be used in a variety of operations, including rock quarries, sand and gravel, mining, recycling, construction aggregates and by road building contractors Materials processed by the Universal Jaw Crusher include limestone, gypsum, concrete, rubble and more Aggregates Concrete Crushing Frac Sand MiningUniversal Jaw Crushers McLanahanFor a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 457/085 = 536 cm and for a shape factor of 17, the width should be = 457 × 17 = 78 cmJaw Crusher an overview ScienceDirect Topics

The twostage crushing system and the crushed concretes

In the first stage, as shown in Fig 3(b) the concrete samples were crushed in the laboratory by the jaw crusher which led to produce folie ceouslike The PRESCREEN also INCREASES overall PRODUCTION and reduces wear by ONLY allowing material into the crusher that needs to be crushed The FOLDING SIDE DIRT CONVEYOR is positioned under the DIRT/PRESCREEN and carries and discharges all of the material that passes through the screen into a neat pile Not your ordinary jaw crusherCrush, Screen and Track The Rebel CrusherJul 31, 2011 Then the next piece in the lineup would be a primary jaw crusher, which at the least should be 22x34 Next would come a magnet to remove the iron from your concrete The primary crusher will only crush it down to a 4 to 5 inch size so if you prefer a smaller spec material your gonna have to add a secondary crusher be it cone, roll, or impactconcrete crushing Heavy Equipment Forums

Can Old Concrete be Crushed for Recycling? FTM Machinery

Nov 29, 2019 Cone Crushers Cone crushers can also be used behind the jaw crusher and the crushed concrete produced by it passes through screens that separate the aggregate into sizes greater than 20 mm and 1020 mm The plus Can Old Concrete be Crushed for Recycling FTM Nov 29 2019 Jaw Crushers Most recyclers use a jaw crusher for primary crushing because it can handle large pieces of concrete and residual reinforcement An excavator loads the concrete into the jaw crusher then it chew the larger chunks of concrete into smaller piecesConcrete Foundation Design Jaw CrusherAug 01, 2019 Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 Mpa2 Types of Concrete Crushers

Universal Jaw Crushers McLanahan

McLanahan Universal Jaw Crushers can be used in a variety of operations, including rock quarries, sand and gravel, mining, recycling, construction aggregates and by road building contractors Materials processed by the Universal Jaw Crusher include limestone, gypsum, concrete, rubble and more Aggregates Concrete Crushing Frac Sand MiningFor a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 457/085 = 536 cm and for a shape factor of 17, the width should be = 457 × 17 = 78 cmJaw Crusher an overview ScienceDirect TopicsMay 06, 2021 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of finished material produced by the crusher Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle Jaw Crusher Working Principle

Recycled Concrete Aggregates Recycling Concrete Fibo

A jaw crusher breaks down the concrete between two verticle jaws A weighted flywheel powers the jaws One jaw is fixed and the other swing jaw moves backwards and forwards The concrete is crushed using compressive force Jaw crushers are versatile and economical They are perfect for processing hard and abrasive materialsPortable mobile jaw crusher is developed according to novel series MTM Trapezium Grinder MTM Medium Speed Trapezium grinder is a kind of leadingworldlevelold jaw type tractor operated rock crusherDec 02, 2017 •Three main crusher types: jaw, cone, and impact –Tell contractor desired gradation/result –Contractor to select crushing process for desired gradation and material properties 19 0 20 40 60 80 100 01 1 10 100 % Korngröße / mm Backenbrecher Prallbrecher Impact Jaw Crusher Particle size, mm singUse of Recycled Concrete Materials in Base/Subbase

concrete crushing Heavy Equipment Forums

Jul 31, 2011 Then the next piece in the lineup would be a primary jaw crusher, which at the least should be 22x34 Next would come a magnet to remove the iron from your concrete The primary crusher will only crush it down to a 4 to 5 inch size so if you prefer a smaller spec material your gonna have to add a secondary crusher be it cone, roll, or impactKomplet LT 7040 Jaw Crusher Crushing Concrete with Rebar to ReUse he Komplet LT 7040 compact jaw crusher was utilized to crush demolition and excavated waste from an old building was recycled onsite Komplet America Mobile Compact Crushers The KJC 704 jaw crusher has been specifically designed for operators for whom versatili Komplet LT 7040 Jaw Crusher Crushing Concrete with Rebar Once the concrete is crushed, screened and made into a highly usable aggregate, it will have a retail value of $15USD to $55USD per ton (depending on your location and buyer) Renting a crusher is also an option if you want to test the waters before buying a machineHow to make money recycling concrete

Use of fine recycled concrete aggregates in concrete: A

Jun 01, 2021 Generally, concrete with crushed aggregates requires slightly higher cement content in order to reach the same workability as a concrete with round aggregates Low workability (reduced slump and slumpflow values) is mostly reported for concrete with fRCA due to higher water demand of fRCA than the same concrete made with river sandrecycling concrete,impact crusher,impact crushersliming Crusher Machine Zhengzhou liming Machinery Co, Ltd is a famous manufacturer of crushing and screening equipment and provides series recycling concrete equipment for Concrete Crushing, Chicago Crusher Mills, Cone Crusher Nov 29, 2019 Cone Crushers Cone crushers can also be used behind the jaw crusher and the crushed concrete produced by it passes through screens that separate the aggregate into sizes greater than 20 mm and 1020 mm The plus Can Old Concrete be Crushed for Recycling? FTM Machinery

Jaw Crusher an overview ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape Assuming in this case the largest particle to be crushed is 85% of the gape, then the gape of the crusher should be = 457/085 = 536 cm and for a shape factor of 17, the width should be = 457 × 17 = 78 cmAug 01, 2019 Jaw Crusher, also known as concrete crusher, is usually used as the primary equipment for concrete crushing It is also suitable for metallurgy, mining, construction, chemical, water conservancy and railway sectors, and used as a device for fine and medium crushing of ores and rocks with compressive strength below 250 Mpa2 Types of Concrete Crushers May 06, 2021 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of finished material produced by the crusher Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle Jaw Crusher Working Principle

Universal Jaw Crushers McLanahan

McLanahan Universal Jaw Crushers can be used in a variety of operations, including rock quarries, sand and gravel, mining, recycling, construction aggregates and by road building contractors Materials processed by the Universal Jaw Crusher include limestone, gypsum, concrete, rubble and more Aggregates Concrete Crushing Frac Sand MiningJul 10, 2019 I have a small 6" jaw crusher that I have run a lot of 4" to 5" stone though and it works fine hand feed I also have a small 12" jaw crusher that we have run some concrete though but we had to brack it up frist to fit in the 12" jaw some rebar was so long that we had to cut and pull it out of the jaw most of the rebar would not go though we did use a loader to fill Jaw Crusher, What Do I Need To Know About Crushing Concrete?Jan 01, 2019 Particle size distribution curves of recycled aggregates from concrete pavement crushed by jaw and impact crushers The jaw crusher produced 85% coarse aggregates (fraction >48 mm), whereas the impact crusher produced 82% coarse aggregates In both cases, the content of particles finer than 015 mm was less than 2% massConcrete aggregates properties crushed by jaw and impact

How Much Money Can I Make Crushing Concrete?

Apr 23, 2019 So, Rick, great question It does have a lot to do with where you’re located So, you know I would look at the New York rates for what crushed concrete is selling for Possibly as a barometer you’d look at the price of crushed stone in your area and that would give you a general idea what you can expect to make if you’re crushing concreteJul 31, 2011 Then the next piece in the lineup would be a primary jaw crusher, which at the least should be 22x34 Next would come a magnet to remove the iron from your concrete The primary crusher will only crush it down to a 4 to 5 inch size so if you prefer a smaller spec material your gonna have to add a secondary crusher be it cone, roll, or impactconcrete crushing Heavy Equipment ForumsCan Old Concrete be Crushed for Recycling FTM Nov 29 2019 Jaw Crushers Most recyclers use a jaw crusher for primary crushing because it can handle large pieces of concrete and residual reinforcement An excavator loads the concrete into the jaw crusher then it chew the larger chunks of concrete into smaller piecesConcrete Foundation Design Jaw Crusher

Crush, Screen and Track The Rebel Crusher

The PRESCREEN also INCREASES overall PRODUCTION and reduces wear by ONLY allowing material into the crusher that needs to be crushed The FOLDING SIDE DIRT CONVEYOR is positioned under the DIRT/PRESCREEN and carries and discharges all of the material that passes through the screen into a neat pile Not your ordinary jaw crusherKomplet LT 7040 Jaw Crusher Crushing Concrete with Rebar to ReUse he Komplet LT 7040 compact jaw crusher was utilized to crush demolition and excavated waste from an old building was recycled onsite Komplet America Mobile Compact Crushers The KJC 704 jaw crusher has been specifically designed for operators for whom versatili Komplet LT 7040 Jaw Crusher Crushing Concrete with Rebar KINSHOFER Group Concrete Crusher Able to crush concrete and cut through steel reinforcements, the DRC crushers can be used for both, primary and secondary demolition and are most appropriate for interior demolition jobs They crush concrete of up to 600 Mm / 2362 in thickness and cut steel reinforcements of up to 28 mm / 110 in diameter crusher used for demolition of concrete

Concrete Recycling Process and Iron Remover Selection

Oct 29, 2019 Damage to the plate of jaw crusher Change the parameters of jaw crusher When the iron enters into the crushing cavity of jaw crusher, the jaw crusher can't crush it cause the iron is too hard When the jaw crusher attempts to crush the iron, the pressure between the jaw plates would be rise immediately, and the power and oil temperature will